Predictive Analytics in Manufacturing: Moving Beyond Static Dashboards

- February 19, 2026

- 0

Manufacturers have never had more data at their fingertips. Machine sensors, production systems, ERP platforms, and quality control tools—every layer of the operation generates information.

Yet for many organizations, that data still lives in dashboards and reports.

Useful? Yes.

Transformational? Not quite.

Predictive analytics takes manufacturing beyond hindsight reporting and into forward-looking decision-making.

Contents

- 1 The Limits of Traditional Reporting

- 2 What Predictive Analytics Really Means

- 3 Predictive Maintenance: Preventing Downtime Before It Happens

- 4 Improving Quality Before Defects Multiply

- 5 Smarter Inventory and Demand Planning

- 6 From Visibility to Intelligence

- 7 Overcoming Common Barriers

- 8 The Competitive Advantage

- 9 The Future Is Proactive

The Limits of Traditional Reporting

Dashboards are valuable. They show performance metrics, highlight trends, and help leaders understand what happened yesterday, last week, or last quarter.

But traditional reports are reactive by nature. They answer questions like

-

What was our downtime last month?

-

How many defects occurred in this batch?

-

Did we hit production targets?

These insights matter—but they don’t prevent problems before they happen.

In fast-paced manufacturing environments, reacting after the fact can be expensive.

What Predictive Analytics Really Means

Predictive analytics uses historical data, machine learning models, and statistical analysis to anticipate future outcomes.

Instead of asking, “What happened?” the question becomes:

-

When is this machine likely to fail?

-

Which production runs are at risk for defects?

-

Where will demand exceed capacity?

-

Which suppliers pose the highest delivery risk?

It shifts operations from reactive firefighting to proactive control.

Predictive Maintenance: Preventing Downtime Before It Happens

One of the most powerful applications of predictive analytics in manufacturing is maintenance.

Rather than servicing equipment on a fixed schedule—or waiting for it to break—predictive systems analyze:

-

Temperature fluctuations

-

Vibration patterns

-

Run-time data

-

Performance deviations

The result? Early warnings that allow teams to intervene before failure occurs.

This reduces:

-

Unplanned downtime

-

Emergency repair costs

-

Spare parts waste

-

Production delays

And most importantly, it protects revenue.

Improving Quality Before Defects Multiply

Quality issues rarely appear out of nowhere. They often begin with subtle shifts in process variables.

Predictive analytics can detect patterns linked to defects and flag production runs at higher risk. That allows adjustments before scrap rates rise or customer complaints increase.

Instead of discovering a problem after shipping a product, manufacturers can correct it in real time.

Smarter Inventory and Demand Planning

Overproduction ties up capital. Underproduction loses sales. Excess inventory strains storage and cash flow.

Predictive models analyze historical sales data, seasonal patterns, market signals, and operational capacity to forecast demand more accurately.

This enables:

-

Better production scheduling

-

Leaner inventory levels

-

Improved supplier coordination

-

Reduced waste

Data becomes a strategic asset, not just a record of past performance.

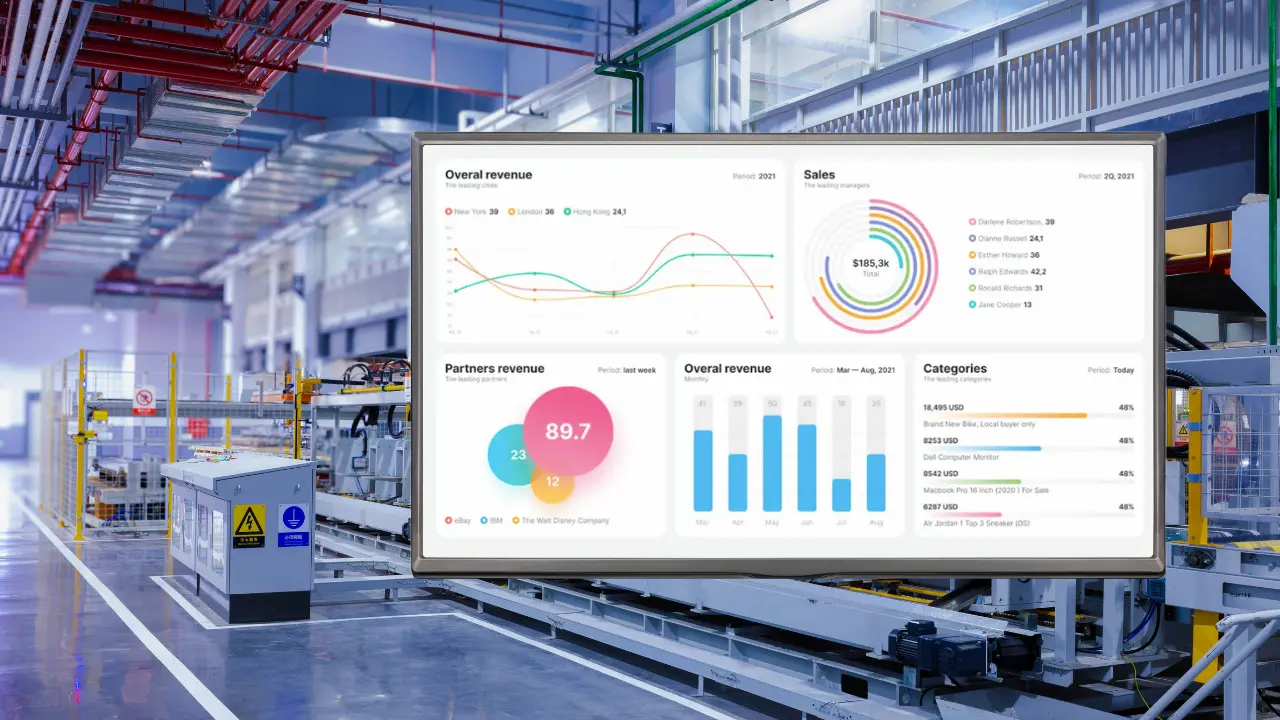

From Visibility to Intelligence

Many manufacturers believe they are “data-driven” because they have dashboards.

But visibility is only the first step.

True operational intelligence means:

-

Systems that alert you before issues escalate

-

Forecasts that guide planning decisions

-

Automated recommendations for process adjustments

-

Continuous learning from real-time data

Predictive analytics transforms data from static snapshots into dynamic insight.

Overcoming Common Barriers

Adopting predictive analytics doesn’t require replacing every system overnight.

A phased approach often works best:

-

Identify high-impact areas (maintenance, quality, demand forecasting)

-

Integrate data sources across machines and systems

-

Develop targeted predictive models

-

Pilot and refine before scaling

Modern cloud infrastructure and scalable analytics platforms make these initiatives more accessible than ever.

The Competitive Advantage

Manufacturers who leverage predictive analytics gain more than operational efficiency. They gain resilience.

They can:

-

Minimize disruption

-

Optimize throughput

-

Improve product consistency

-

Make confident, data-backed decisions

In competitive markets, the difference between reacting and predicting can determine profitability.

The Future Is Proactive

Dashboards tell you where you’ve been.

Predictive analytics tells you where you’re going—and how to prepare.

Manufacturing is evolving from observation to anticipation. Organizations that embrace predictive intelligence move from managing problems to preventing them.

And that shift changes everything.